Choco Chocos Honey Cheerios Loops Cereals Processing Plant

Basic Info.

| Model NO. | JY-FR |

| Application | Wheat, Corn, Wheat, Maize |

| Voltage | 380V |

| Appearance | Biaxial |

| Press Materials | Corn |

| Press Series | Fourth |

| Condition | New |

| Customized | Customized |

| Installation | Engineer Guidance |

| Motor | Siemens or Chinese Brand |

| Name | Honey Cheerios Oops Cereals Processing Plant |

| Produce Name | Choco Chocos Loops Cereals Processing Plant |

| Raw Material | Corn, Maize, Wheat |

| Prodcut | Corn Flake, Breakfast Cereals |

| Material | Stainless Steel |

| Transport Package | Container |

| Specification | According to Model |

| Trademark | Joyang |

| Origin | China |

| HS Code | 84388000 |

| Production Capacity | 1 Set/Month |

Packaging & Delivery

Package Size 1200.00cm * 1200.00cm * 100.00cm Package Gross Weight 1000.000kgProduct Description

PufChoco Chocos Honey Cheerios Loops Cereals Processing PlantChoco Chocos Honey Cheerios Loops Cereals Processing PlantProduct DescriptionProduct Description

Choco Chocos Honey Cheerios Loops Cereals Processing Plant can produce breakfast cereal which is one kind of nutritional convenient food which is produced by this process line, using grist as basic material, with different shapes, such as, granule, flake, animal, etc. One outstanding characteristic of the breakfast cereal is that it contains abundant compound carbohydrates and dietary fibre, strengthens lots of microelements, such as vitamin and mineral, and also can be added with cocoa and sugar, like honey and maltose. It can be drunk directl after mixed into coofee, milk, yoghourt or fuctional drink. Children can eat breakfast cereal as sweet crispy sanck.

Product Parameters

| Model | Installed Power | Power Consumption | Production Capacity | Dimesion |

| JY65 | 140kw | 90kw | 120 - 150kg/h | 39*2*2.5m |

| JY70 | 160kw | 120kw | 200 - 250kg/h | 41*2*2.5m |

| JY85 | 190kw | 140kw | 300 - 400kg/h | 42*2*3.5m |

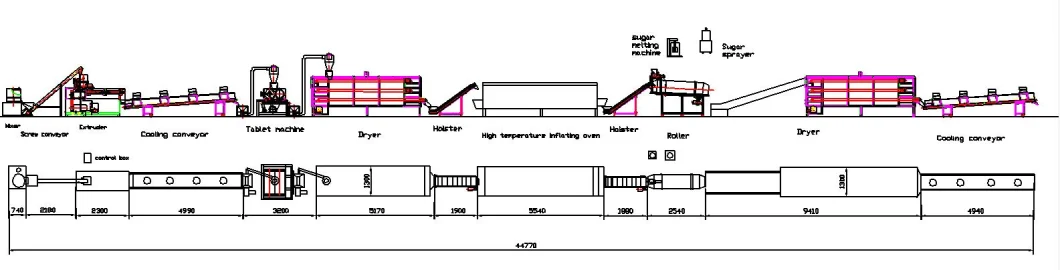

Flowchart Diagram

Machine List In Choco Chocos Honey Cheerios Loops Cereals Processing Plant

Mixer→Screw Conveyor→Twin Screw Extruder→Cooling Conveying→Flaking Machine→Air Conveyor→Three Layer Oven→Hoister→Baking Oven→Melting Sugar Machine→Sprayer Sugar→Hoister→Roller→Five Layer oven→Cooling Machine

Major Equipment

Mixer | It is a mixer which can mix all the raw materials (powder form) with water and liquid chemical additives. |

Extruder | The twin screw extruder is made of the feeding system, extruding system, cutting system, heating system, lubrication system and controlling system. 1. The screw are made of the alloy steel. 2. The forced lubrication system. 3. Auto-temperature control system. 4. Auto-speed control system. 5. Self-cleaning. |

Cooling Conveyor | This machine can make the food be cool avoiding sticking together and be suitable for packing. The total length of the conveyor is 5 meters. It is full set stainless steel. The height of the hoister can be adjusted based on the requirement. |

Flaking Machine | This machine is to make the balls made by extruder to flakes. |

Dryer | The heating way is electricity heating. It is used for drying. The net belt running speed can be controlled to change the food drying time in the dryer. The temperature also can be controlled. Multi-layer dryer is with compact size than other type dryers. |

Baking Oven | Hot air baking oven can inflate and puff the corn flakes crispy and crunchiness with bubbles. The temp of the heating plates is around 300 degree. That is the reason why the corn flakes can be crispy and crunchy aspect in 10 seconds. We control the belt speed to make the corn flakes be cooked in the oven for the right time. |

Melt Sugar Machine | This machine can melt the sugar as the liquid. |

Sugar Sprayer | With the special screw pump, this machine can inject chocolate, butter, and sugar on the corn flakes. This machine can also that the core and keep the temperature. |

Customer & Service

We exported the machines to many countries all around the world,such as ltaly, German, Russia, Turkey, Australia, Indonesia, India etc. Almost all the customers speak highly of our machines and service,and they continue to buy from us again and again.1.One year complete warranty.2.Free consultation service before during and after sales.3.Provide basic production techniques and formulas.4.Overseas installation and training of equipment maintenance and operating personally.5.Debugging and inspecting of equipment until everything is functional before leaving the factory.

Packaging & Shipping

1.Daub coal oil on the surface of the machines.2.Plastic film as the inner packing.3.Train, ship or depend on clients' requirement.

Company Information

Shandong Joyang Machinery Co., Ltd. is a professional supplier of Choco Chocos Honey Cheerios Loops Cereals Processing Plant Our conmpanys motto is:" Service and quality are equally important". We are located in jinan, the Capital of Shandong Province. Shandong Joyang Machinery Co., Ltd. is vested with many staffs with many years of experience in various applications of machines.Our main products include snacks making machine, pet food making machine, fish feed making machine, soya protein making machine. All the machines can be customers to meet their various demands. We exported the machines to many countries all around the world, such as Italy, German, Russia, Turkey, Australia, Indonesia, India etc. Almost all the customers speak highly of our machines and service, and they continue to buy from us again and again.Whatever machine you need from China, contact Shandong Joyang Machinery Co., Ltd., please. We will supply you high quality machines with best solution based on our strong techiques and rich experience.

FAQ

Q:How long is your guarantee time?

A:One year after commissioning.

Q:How is the installation?

A:We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Q:If we show you our layout of factory, can you help to design the whole process line?

A:Of course, our experienced engineers and technical employee can help you to arrange the layout and installation of whole production line based on your real situation.

Q:How long is your delivery time?

A:Generally it is 7-10 days if the goods are in stock, or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q:Will you help us if we accrue any problems in the future production?

A:Yes, we will always at your service. You can contact me via mobile, whatsapp, skype, viber, wechat and so on. I will help solve your problems as soon as possible.